As simple as it is to connect devices in AS-Interface networks using the profile cable and piercing technology, so challenging could be the configuration for complex automation solutions such as zero pressure accumulation or muting. With Bihl+Wiedemann you don’t notice any of this, since the user interfaces of the software products – and thereby the overall user experience – is being constantly improved. The same applies to the company’s devices such as the ASi-5 Module BWU4386 with eight IO-Link Master Ports.

IO-Link integration using ASIMON360.

Good technology like ASi-3, ASi-5 or IO-Link gets on one hand even better when it is easy to further develop, optimize and update it. On the other hand it gets also even better when the operator never even notices the technological complexity that resides in the background, whereas the user interface enables simple, clearly structured and intuitive operation to provide a positive user experience. And good technology gets even better when ongoing enhancement of the firmware and the PC configuration software also takes into account feedback and suggestions from users. Which is how things are done at Bihl+Wiedemann, where both the device firmware and the PC software are continually improved in interaction with customers.

Responding flexibly to customer demands and market conditions with firmware updates

In these times when many components are in short supply and all delivery times are long, Bihl+Wiedemann has recognized the potential that firmware updates can offer. They always make it possible for the company to make new ASi devices available to users at an early stage for testing, to integrate customer wishes on short notice, to implement and validate new functionalities and thereby to reduce the time-to-market of the solution for all. Prototypes and products remain always with the customer and can – simply through firmware updates via internet taking into account all the important security aspects – be improved efficiently and with time savings together with the later users. Service and support can benefit from this approach as well, since in many cases sending hardware back and forth is no longer necessary in favor for a quick firmware update. Close cooperation with customers – such as when implementing their first ASi application, at (first-time) commissioning of prototypes or testing series products as part of a system configuration – ensures that the firmware gets continually more robust. In some cases even non-specified settings or values can be “compensated“, e.g. at IO-Link products from other manufacturers.

PC software focuses on positive user experience

The continual improvement in the usability of the software tools has as its goal that users enjoy working with it and have a positive user experience. When further developing user interfaces particular emphasis is placed on representing more complex, autonomous control functions as simply as possible. ZPA, zero pressure accumulation for buffer sections in stationary conveyor systems, or the safety function muting for securing hazardous areas with continual material feed are two examples of applications with complex configuration and logic which can be implemented simply with the help of the intuitive software suites from Bihl+Wiedemann without the need for PLC programming. A feedback function in the latest software releases ensures that the desires and requirements of customers are better identified, understood and ultimately realized. This way the careful checking and clustering of feedback are used to turn individual suggestions into innovations for every user of ASi and IO-Link modules offered by Bihl+Wiedemann.

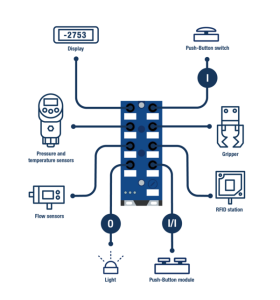

The ASi-5 Module BWU4386 with eight IO-Link Master Ports uses, when needed, Pin 2 for configuring an additional in- or output on any port.

Cost-effective and flexible to use: BWU4386 with eight IO-Link Master Ports

Yet another example of how customers can benefit from the combination of continuously improved PC software and product development is the ASi-5 Module BWU4386, the first 8-port IO-Link Master that gets connected using profile cable and piercing technology. The device is constructed such that each of the eight IO-Link master ports class A provides not only its function as an interface for IO-Link devices but also a standard I/O signal. Pin 2 of the five-pole M12 port socket can thus be configured if needed as an additional in- or output – easily and conveniently using the software suite from Bihl+Wiedemann. The continual further development of the PC software user interface also ensures here that the user can make all the settings as intuitively as possible and is not even aware of the complexity in the background.

The ASi-5 Module BWU4386 with eight integrated IO-Link Master Ports is in contrast to comparable IO-Link masters with eight ports not only more flexible, but also more cost-effective. Comparing the module costs in a system with other IO-Link masters, users can expect connection costs of less than 25 Euros per port. With as few as ten IO-Link devices this means a savings of up to 18% – or even 60% for 200 devices. Similarly clear are the cost advantages in a system comparison with IO hubs from other manufacturers

Supply IO-Link device class A with two-conductor cable directly out of ASi-5

One of the latest product highlights from Bihl+Wiedemann is the new ASi-5 Module BWU4748 with integrated IO-Link Master Class A for one IO-Link device. The active distributor enables the supply of the connected IO-Link device directly from ASi, with no additional auxiliary power required. Connected with piercing technology on the ASi profile cable, the two-conductor ASi line becomes an IO-Link communication interface which transmits both power and data on the same cable. Typical use cases for such connections include suspended conveyors or shuttle systems – in other words, locations where it is difficult to bring auxiliary power to the sensor.

Whether firmware updates, software with optimal user experience or new hardware in the form of products for ASi-5 and IO-Link – Bihl+Wiedemann always has customer and user satisfaction in view when developing all of their products. Because only in this way can come impulses which yields technologically lasting and future-proof innovations.