Flawless integration of frequency inverters, DC drives and roller drives

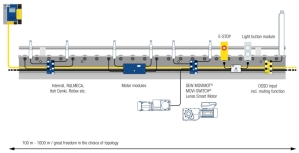

Drive and conveyor applications are an ideal field of application for AS-Interface. This is because the advantages of the simple wiring system are extremely effective in all fields – e.g., in warehouse and material flow engineering, conveyor and sorting systems, shuttle pallet warehouses, order-picking systems, packaging systems, and also in storage and retrieval machines. The main advantages of ASi are: Voltage supply and communication via a single cable, extremely simple wiring thanks to piercing technology, complete freedom of topology, plus the transmission of safe and unsafe signals on the same cable.

Also, very important: You can easily combine ASi-3 and ASi-5 in one application to perfectly address the respective requirements. Uncomplicated functions such as start/stop, left-right run, or open/close can be implemented in the simplest and most cost-effective way with our ASi-3 modules. With its high transmission speed and large data size, ASi-5 is ideally suited for solving demanding applications. For example, with all ASi-5 drive modules you benefit from cyclic writing of speeds and ramps along with detailed diagnostics.

Find out about our comprehensive range of solutions for drives from leading manufacturers.

How you can benefit from AS-Interface in drive technology

All Bihl+Wiedemann actuator solutions offer you the same proven ASi advantages at all times. Among others, these include:

- Just one cable for both data and power – in contrast to parallel wiring, no complex cable harnesses are required. This considerably reduces material and assembly costs.

- Great freedom in selecting the topology – each ASi module can be assembled at any point along the ASi professional cable. For example, it is possible to configure star, ring, or linear structures.

- Extremely simple installation – ASi modules are simply plugged onto the ASi profile cable using piercing technology and are thereby protected against reverse polarity; the cable is taken from the cable reel in the desired length. There is no need whatsoever to cut, strip, and screw the cable, as is necessary when using round cables.

- Integrated safety technology – safe and unsafe signals can be transmitted on the same cable. As a result, you eliminate the need for the duplicate infrastructure, which was previously necessary.

- Efficient integrated power distribution for 24 V and 48 V motorized rollers – for this purpose, the additional AUX cable provides 20 W, 35 W, or up to 50 W per roller. Here you can find further information about our 48 V drive solutions.

- Decentralized control of three-phase drives/frequency inverters – this allows you to create simpler system structures, regardless of whether you prefer binary or serial control.