MUTING: MORE EFFICIENT THROUGH THE “HOLE IN THE GUARD FENCE” WITH ASi-5 SAFETY

Material yes, people no – this distinction is what muting is all about. This safety function enables safe, automated material transport into and out of hazardous areas in stationary conveyor systems. ASi-5 Safety and the new Muting Module BWU4411 from Bihl+Wiedemann give new performance and cost advantages for this safe path through the “hole in the guard fence”.

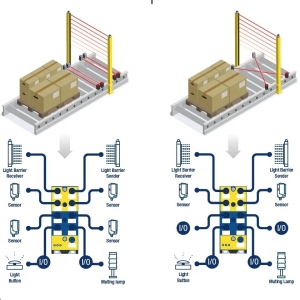

“Gatekeeper for the hole in the guard fence”: with the ASi-5 Safety Muting Module BWU4411 from Bihl+Wiedemann, muting applications with and therefore machine safety up to SIL3 and PLe can be realized. Connected via the yellow ASi profile cable, it represents the single, central collection point for all muting components and their I/O signals. The module requires only a single ASi-5 address in the safety network for this purpose – which significantly reduces hardware and addressing effort.

It features an integrated power supply connection for a contactless protective device and can be easily configured via the Bihl+Wiedemann ASIMON360 safety software. In operation, the BWU4411 provides the user with important diagnostic data while offering connectivity into the IIoT via the company’s ASi-5/ASi-3 fieldbus gateways, if required. Purchasing departments are happy as well, since the cost of the ASi-5 Safety Muting Module is only a third that of comparable solutions of this type on the market.

Safety for material pass-throughs in the guard fence

Muting – a term that describes the controlled suppression of the protective function of a contactless protective device, e.g. a safety light curtain or a light barrier – is used in a variety of intralogistic tasks. The function makes it possible to perform automated material transport in machines located inside a safety fence or other mechanically separating protective device.

Muting is used especially in highly automated machines and systems – e.g. in robot cells in the automotive industry, turntable and lifting table stations in stationary material handling, transfer vehicles in the front zone of a high-bay warehouse, strapping and film wrapping machines, or multi-side labelers for pallets.

Despite all the automation, people can still be present in areas that are not actually accessible and can therefore be exposed to hazards from machine movements – operators, service technicians, maintenance personnel, but also unauthorized persons. Therefore, a safe distinction between man and material is essential at the ‘open’ access points to the hazardous areas.

The ASi-5 Safety Muting Module from Bihl+Wiedemann supports all industry tandard muting signals. This allows both sequential muting and cross muting up to SIL3/PLe.

Muting solution from Bihl+Wiedemann uses potentials

This process engineering challenge is not new – and yet, many muting solutions lack technical and economic efficiency. Alternative solutions to ASi Safety usually have to be laboriously wired using expensive, preassembled Ethernet cables. Bihl+Wiedemann’s implementation stands out here not only because of the module costs, but also because of the piercing technology used with AS-Interface. This minimizes costs and errors during installation. The simple, intuitive configuration via the ASIMON360 safety software is also a key feature – an option that not every muting solution has by a long shot.

For IIoT-compliant integration, it is also of little help if, in the case of Ethernet-based solutions, numerous IP addresses are required for multiple muting areas in a single application due to the large number of components, or if no direct data transfer to IT systems is possible – a function that all ASi-5/ASi-3 fieldbus gateways from Bihl+Wiedemann support. And finally, previous muting solutions are often real cost factors for many users due to their scope or technical structure. Although muting has been possible in various ways for a long time, it is only now becoming really smart and cost-effective with ASi-5 Safety.

The smart solution: the new ASi-5 Safety Muting Module BWU4411

In recent months, Bihl+Wiedemann has consistently expanded its portfolio of solutions for ASi-5 Safety, including certified input modules designed to meet different requirements (see info box). In this context, the ASi-5 Safety Muting Module BWU4411 with protection rating IP67 was also developed – including 1-channel and 2-channel safe muting signals and, depending on the configuration, up to eight standard inputs or outputs. It supports all industry-standard muting types – cross muting, in which the two muting sensors must respond simultaneously to trigger the muting cycle, as well as the various forms of four-beam sequential muting.

Concerning the latter, several sensors are connected in series and must respond in a specific sequence to activate muting. In parallel, the new muting module also collects the signals of all connected standard sensors and integrates components such as reset buttons or muting lamps into the application.

The muting function can be created automatically in the ASIMON360 safety software from Bihl+Wiedemann – alternatively, the signals can also be transmitted to a safety control via a safe fieldbus protocol, such as PROFIsafe, and used there for bridging. With ASi-5 Safety, muting can be efficiently implemented in a single piece of hardware – especially since AS-Interface as a wiring technology makes the connection of the components via piercing technology extremely simple, safe and economical. And the module itself is also a winner in terms of cost: it is more than 60% less expensive than com- parable Ethernet-based solutions from other suppliers.

Maximum convenience with AS-Interface

Solutions using AS-Interface and ASi Safety – ASi-5 and ASi-5 Safety included – represent not only economic efficiency, but also simplicity and flexibility. Since suitable gateways are available for many common fieldbuses, once a solution has been created, it can be easily and cost-effectively adapted to other requirements – such as when a new control is required in the project. In such cases only the gateway needs to be replaced. With AS-Interface, several identical muting applications in an installation can be transferred without any problems using copy and paste and then configured under a single IP address, addressed by the control and analyzed in the event of a problem.

If a module should ever fail, the complete configuration is automatically transferred to a replacement module, which reduces downtimes to a minimum. Additional safety devices can also be integrated on the same ASi line, as well as complex standard modules such as IO-Link masters, all while retaining the familiar advantages of ASi and ASi Safety. AS-Interface thus offers all the prerequisites for finding the optimum solution for every application.

With the BWU4411 muting module from Bihl+Wiedemann, muting applications can now be implemented much more efficiently, both technically and, above all, economically. The company based in Germany also offers, together with the already existing I/O, IO-Link, motor and counter modules, the new ASi-5 safety input modules and the ASi-5/ASi-3 gateways with OPC UA server, future-proof solutions for stationary material flow and material handling from a single source.