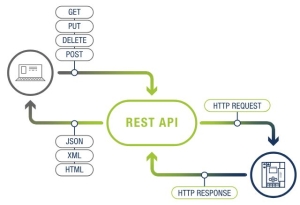

REST-API – The easy way to access your machine and process data

Modern ASi-5/ASi-3 Gateways all feature a REST-API interface that provides you with effortless and direct access to machine data and system information – with no impact on ongoing fieldbus communication. The REST API interface is particularly advantageous for data exchange and seamless integration with various software systems, such as ERP, MES, as well as web and cloud applications.

The gateway serves as an ideal edge device for a wide range of IIoT applications: It gathers data and makes it available to higher-level systems for analysis and processing. IIoT applications can use the REST-API for flexible access to the necessary data. This enables the monitoring of processes as well as the recording and distribution of process data within corporate and production systems. Our gateways facilitate easy integration into digital networks and contribute to increased efficiency in modern industrial environments.

How to benefit from the REST-API interface

Our modern ASi-5/ASi-3 Gateways offer an extensive range of API endpoints to retrieve specific data and parameters of connected machines and peripherals. With the appropriate API calls, machine and process data can be queried and integrated into IT systems, cloud applications, or web browsers. Utilize these endpoints to execute existing apps and services like condition monitoring and device management.

- Direct access to selected ASi-3 and ASi-5 device data: Access is achieved through structured API endpoints, with output in an easy-to-understand JSON format that can be read by both humans and machines.

- Simple integration: Thanks to the standardized HTTP request structure, the REST-API can be integrated into existing IT systems, web applications, and cloud environments without significant development effort.

- Flexible live data exchange for IT and web applications: Monitor production processes by retrieving input and output data. The data can be used for visualization in web applications or integrated into databases for further analysis.

- Remote diagnostics and maintenance: Access vital diagnostic information such as module temperature, voltage, and error lists to detect anomalies early and implement preventive maintenance. You can also view the current status of safety modules or Safe Link nodes to ensure operational safety.

- Compliance with cybersecurity standards: Data is encrypted via HTTPS with TLS. Additionally, network ports connected to the REST-API can be blocked by the user locally at the ASi Gateway.

Link to more information: https://www.bihl-wiedemann.de/dk/applications/communication/rest-api