Self-Configuring I/O Modules – Flexible, Cost-Effective, Simple Commissioning

What are Self-Configuring I/O Modules?

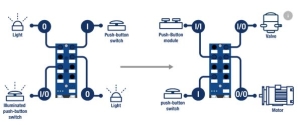

Self-configuring digital I/O modules are a new Bihl+Wiedemann product family. “Self-configuring” means: If you set an output bit in the PLC output data, it is an output with a diagnostic feedback in the corresponding input bit. If you do not set an output bit in the PLC output data, it is automatically mapped as an input signal in the PLC input data. This allows many different applications to be realized with the same module. The modules are especially also a great alternative to comparable Ethernet or IO-Link-based I/O solutions. You not only save on the module price but also on the wiring costs. You also benefit from channel-specific diagnostics.

For example, the new I/O technology with two signals per M12 allows you to conveniently realize the following applications:

- Drives with binary control: e.g., Lenze Smart Motor or SEW MOVI-SWITCH

- Sensors with one or two switching points: e.g., inductive proximity sensors

- Control panel elements: e.g., an illuminated pushbutton

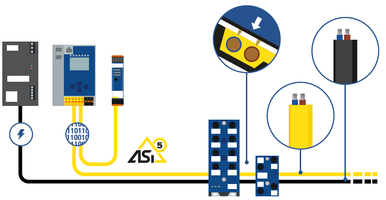

We currently offer self-configuring modules with 4 I/Os, 8 I/Os and 16 I/Os, for which the ASi/AUX connection is established via profile cable, M12 connector or push-in terminal, depending on the product variant. Thanks to ASi-5, each of the 16-or 8-bit bidirectional process data is consistently transmitted in just 1.27 ms.

Cost-effective in Hardware and Wiring

- Modules are more inexpensive than comparable I/O solutions based on Ethernet or IO-Link

- Up to 70 % lower wiring costs compared to round cable solutions

- Reduced wiring complexity thanks to piercing technology and free choice of topology (e.g., ring, star, tree) for energy and communication

- Cost-effective digital outputs